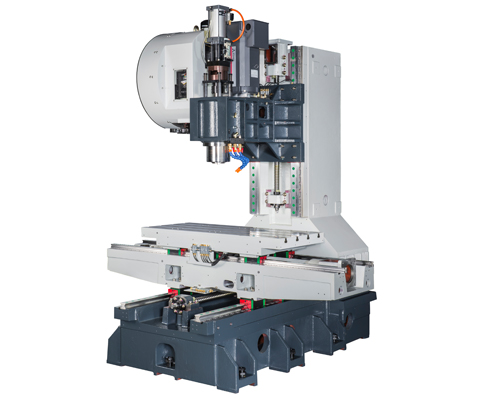

Outstanding Features:

- Linear guideways are professionally mounted and adjusted to guarantee superior feed accuracy and long service life.

- High-speed technology with advanced servo mechanisms and can add direct drive spindle.

- Excellent versatility and superb rigidity is offered-all at most competitive prices.

- The machine adopts a box structure for the base and a trapezoid structure in the column for maximum rigidity.

Specification

| Model | QMC-850 | |

|---|---|---|

| TRAVEL | X x Y x Z axis | 850 x 550 x 560 mm |

| Spindle nose to table | 120~680 mm | |

| Spindle center to solid column surface | 600 mm | |

| TABLE | Working area | 950 x 500 mm |

| Max. loading | 500 kg | |

| T-Slots (No. x Width x Pitch) | 4 x 18 mm x 125 mm | |

| SPINDLE | Tool shank | BT-40 |

| Speed | 10,000 rpm | |

| Transmission | Direct-Speed Belt Drive | |

| Bearing lubrication | Grease | |

| Cooling system | Oil cooled | |

| Spindle motor max.rating (MITSUBISHI) | 7.5kw (10HP) | |

| Spindle motor max.rating (FANUC) | 11kw (15HP) / 15kw (20HP) | |

| Axis motor max.rating (MITSUBISHI) | 1.5 / 2.2 / 3.0 kw | |

| Axis motor max. rating (FANUC) | 1.8 / 1.8 / 2.5 kw (STD) 3.0 / 3.0 / 4.0 kw (OPT) |

|

| FEED RATES | Rapids on X & Y & Z axis(linear way) | 36 / 36 / 25 m/min |

| Max. cutting federat | 10 m/min | |

| TOOL MAGAZINE | Tool storage capacity | 24 arm |

| Type of tool (optional) | BT- 40 (CAT- 40) | |

| Max. tool diameter | 100 mm / 76 mm | |

| Max. tool weight | 7 kg | |

| Max. tool length | 300 mm (arm) | |

| AVG.CHANGING TIME (ARM) |

Tool to tool | 2.7 sec. |

| Chip to chip (50% Z axis) | 6.7 sec. | |

| Air source required | 6 kg / c㎡ up | |

| ACCURACY | Positioning | P0.01 mm |

| Repeatability | Ps0.006mm | |

| DIMENSION | Machine weight | Approx 5,900 kg (arm) |

| Power source required (KVA.) | 15 KVA | |

| Floor space (L x W x H) | 2,700 x 3,000 x 2,870 mm | |

| Shipment advice | 1 x 40'HQ (3 sets) |

Standard Accessories

- Mitsubishi M80 controller, 10.4" LCD

- Spindle speed 8,000 / 10,000 / 12,000 / 20,000 rpm(depend on machine model)

- Automatic tool changer

- Full splash guard

- Heat exchanger for electric cabinet

- Automatic lubricating system

- Spindle oil cooler

- Spindle air blast system (M code)

- Spindle air blow system

- Spindle orientation

- Coolant gun and air socket

- Leveling kits

- Removable manual & pulse generator (M.P.G.)

- LED light

- Rigid tapping

- Coolant system and tank

- Cycle finish indicator and alarm lights

- RS-232C interface with cable (10 m)

- Tool Box

- Operational and maintenance manual

- Transformer

- Spindle coolant ring(M code)

- Chip flush

Optional Accessories

- Spindle speed 12,000 rpm (Belt type)

- Spindle speed 15,000 rpm (Direct drive)

- Coolant through spindle (CTS)

- German ZF gear box

- Automatic tool length measuring device

- Automatic work piece measurement system

- CNC rotary table and tailstock

- Oil skimmer

- Link/Screw type chip conveyor with chip bucket

- Linear scales (X/Y/Z axis)

- Coolant through tool holder

- Table working area:900x410mm(QMC-600)