– Gantry Type

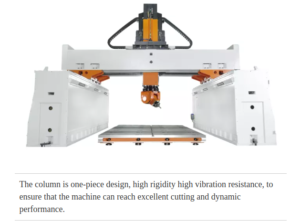

– Column One-Piece Design

– Box in Box Symmetrical Design

– X/Y-Axis Linear Motor Drive

– Feedrate: 60 m/min

– Direct-Drive Motor Two-Axis Milling Head

Gantry Type

Overhead, weight-optimized and structurally rigid portal moving tn the X-axis, for high dynamic performance and precision.

Specifications

| Specifications | Unit | Linmax B-22 | Linmax B-25 | Linmax B-30 | Linmax B-35 | Linmax B-40 |

| Mold | 2232/2240/2200 | 2540/2550/2500 | 3050/3060/3000 | 3550/3560/3500 | 4050/4060/4000 | |

| X-axis Travel | mm | 3200/4000/∞ | 4000/5000/∞ | 5000/6000/∞ | 5000/6000/∞ | 6000/8000/∞ |

| Y-axis Travel | mm | 2200 | 2500 | 3000 | 3500 | 4000 |

| Z-axis Travel | mm | 1250 | 1250 | 1250 | 1250 | 1250 |

| Table | ||||||

| Table long | mm | 3200/4000/∞ | 4000/5000/∞ | 5000/6000/∞ | 5000/6000/∞ | 6000/8000/∞ |

| Table width | mm | 2000 | 2200 | 2700 | 3200 | 3700 |

| T-slot size (width) | mm | 28 | ||||

| Table load | Kg/㎡ | 5000 | ||||

| Distance between spindle nose | mm | 200-1450 | 200-1450 | 200-1450 | 200-1450 | 200-1450 |

| Distance between column | mm | 3290 | 3590 | 4090 | 4590 | 5090 |

| Freedrare | ||||||

| X/Y/Z-axis rapid feedrate | m/min | 60/60/50 | 60/60/50 | 60/60/50 | 60/60/50 | 60/60/50 |

| Auto tool changer | ||||||

| Tool shank | type | HSK A63 | HSK A63 | HSK A63 | HSK A100 | HSK A100 |

| Tool magazine capacity | pcs | 30 | 30 | 30 | 30 | 30 |

| Max. tool weightt | kgs | 8 | 8 | 8 | 15 | 15 |

| Max. tool length | mm | 350 | 350 | 350 | 350 | 350 |

| Max. tool diameter | mm | Ø 75 | Ø 75 | Ø 75 | Ø 125 | Ø 125 |

∞=or more

The Company reserves the right to change, with all the technical specifications of the contract-based technology.

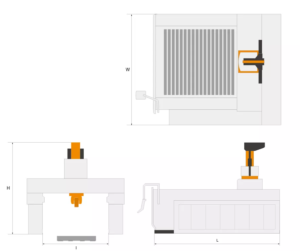

Machine Layout

Accessories

Standard

- The Heidenhain TNC-640 controllers, X, Y, Z, B, C five-axis continuous.

- Heidenhain Handwheel-HR520.

- European modular 2-axis milling head TCH-19(A63).

- The European system of vertical spindle HSK A63 24000 rpm.

- HSK A63 30 tool magazine.

- X / Y linear motor direct driven .

- 12 roller linear guideways (Each 4 sets for X / Y / Z axis ).

- 4 Heidenhain linear scale ( 2 sets for X-axis 2 sets for Y / Z axis ).

- Electrical cabinet temperature control device.

- X / Y linear motor, spindle cooling system.

- Spindle oil-mist device.

- piral-type chip conveyor and rear-type chip conveyor containing iron filing cars.

- Front and rear working door safety interlock (each type).

- Waterproof work said light.

- Machine all parts and a variety of instrumentation unit of measurement.

- Used in all meta international system of units (si) standards.

- Guards cabinet with variety of electrical protection, filtration, ventilation and air-conditioning system.

- Machine standard color.

Option Accessories

- TCH-19(A100) Mobular 2-axis Milling Head + 15,000rpm Spindle

TCH-20(A63) Mobular 2-axis Milling Head + 24,000rpm Spindle

TCH-20(A100) Mobular 2-axis Milling Head + 15,000rpm Spindle

TCH-25 Mobular 2-axis Milling Head + 13,000rpm Spindle - ACT System Magazine Capacity;(option).

(HSK-A100)-60 tools.

(HSK-A63)-60 tools. - Laser Tool Measuring System

- Touch Probe for Workpiece Measuring.

- Coolant through Spindle (CTS) 20/30/40 Bar.

- Transformer.

- Voltage stabilizer

- GPS(Global Pgm Setting) Hand wheel function.

- Blum from control comparison software.

- Automatic Kinematics 5-axis compensation function.

- HEIDENHAIN wireless Handwheel-HR 550

- Enclosed rooftop

- Oil mist recovery system

- Chain-type chip conveyor on both side of worktable area

(Suitable for aircraft industry application)