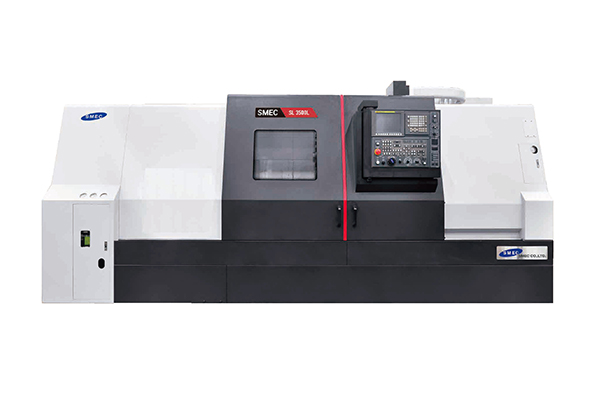

Strongest in its class with superb structural design.

Simultaneous heavy duty and precision turning.

Strongest in its class with superb structural design.

Simultaneous heavy duty and precision turning.

- 30 degree torque tube type bed to support heavy duty turning

- Significantly reduced non-cutting time and efficient turning

- Low-center of gravity reducing vibration, thermal deformation and improving rigidity

Specifications

| DESCRIPTION | SL 3500Y | ||

| Chuck | Chuck size | inch | 12" |

| Capacity | Swing over bed | mm | 850 |

| Swing over cross slide | mm | 850 | |

| Max. turning diameter | mm | 430 | |

| Max. tuning length | mm | 539 | |

| Max. machining length | mm | 2125 | |

| Spindle | Spindle speed | rpm | 2500 |

| Spindle nose | ASA | A2-11 | |

| Draw tube ID | mm | 103 | |

| Spindle bore diameter | mm | 115 | |

| Spindle motor (Cont./Max) | kW | 18.5/26 | |

| Travels | X-axis travel | mm | 280 |

| Y-axis travel | mm | 130 (±65) | |

| Z-axis travel | mm | 2200 | |

| X-axis Rapid traverse rate | m/min | 30 | |

| Y-axis Rapid traverse rate | m/min | 10 | |

| Z-axis Rapid traverse rate | m/min | 30 | |

| Turret | Number of tool stations | ea | 12[24] (BMT65) |

| Turning tool shank size | mm | 25 | |

| Boring bar diameter | mm | 50 | |

| Turret index time(next station swivel time) | sec | 0.20 | |

| Rotary tool speed | rpm | 4500 | |

| Rotary tool motor (Cont./Max) | kW | 5.5/7.5 | |

| Tailstock | Quill diameter | mm | 110 |

| Quill stroke | mm | 100 | |

| Spindle taper | MT | MT4 (Built-in) | |

| Machine | Size (with Side Chip conveyor) L×W×H | mm | 5,450(6,506) × 2,162 × 2,289 |

| Size (with Rear Chip conveyor) L×W×H | mm | - | |

| Machine weight | kg | 10500 | |

| Coolant tank capacity | Liter | 261 | |

| Electric power supply | kVA/V | 50/220 | |

| Controller | FANUC, SIEMENS | ||